The Future of Lithium Refining in India: Are We Ready?

As electric vehicles (EVs), renewable energy storage, and battery-dependent technologies surge forward, lithium refining is emerging as the pivotal link in India’s clean-energy future. While India has long depended on imports for critical battery-grade lithium, upgrades in domestic capability and pipeline projects are signaling a transformative leap.

India’s Lithium Readiness: Reality & Ambition

In February 2023, the Geological Survey of India announced a discovery of 5.9 million tonnes of lithium in Jammu & Kashmir—now ranked as the 7th largest known deposit worldwide. Yet, the clay-based nature of the resource presents extraction and purification challenges. Commercial-scale processing from these reserves is projected to take 4–7 years, emphasizing the need to fast-track upstream investments.

Today, India imports virtually all of its battery-grade lithium, exposing the nation to global supply risks and limited bargaining power. This dependency highlights the urgency of building local refining infrastructure.

Global Trends Support India’s Move

China currently dominates 60–80% of global lithium refining capacity, offering battery-grade lithium carbonate and hydroxide at scale. India is prioritizing partnerships across Australia, US, Russia, and South America to diversify sourcing.

New opportunities are emerging in battery recycling. Scientists in Gujarat have developed a method to extract lithium at 97% purity from spent batteries within just a few hours—a leap toward more sustainable refining.

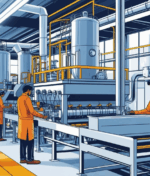

Vardhaan Lithium: Anchoring India’s Strategy

Vardhaan Lithium (I) Pvt. Ltd. is constructing India’s first integrated lithium refinery and Li-ion battery facility in Butibori, Nagpur, Maharashtra. The ₹42,532 crore project spans 500 acres, with a planned refining capacity of 60,000 tpa and battery output of 20 GWh/year.

The company has secured environmental clearance for its Zimbabwe mining venture, ensuring upstream supply. Processing is expected to begin imminently, positioning Vardhaan as one of India’s earliest operational refiners.

Collaborations with leading U.S. and European technology providers support the use of globally accepted battery-grade refining methods and digital automation.

Building Local Capacity and Circular Economy

Battery recycling presents a complementary path. India is scaling facilities that can recover up to 95% of lithium from end-of-life batteries, fostering sustainability and reducing import costs.

Establishing domestic refining capacity now provides readiness to tap into India’s own lithium reserves when they become commercially viable. This forward-looking strategy aligns with both industrial scaling and resource Nation-building.

Final Outlook

India stands at the threshold of a sustainable lithium future—from importer to potential global supplier. While technical hurdles persist, including ore processing and resource commercialization, efforts led by Vardhaan Lithium and government-backed programs bring strong momentum to the ecosystem. As recycling scales and new sourcing partnerships blossom, India is building the infrastructure, expertise, and resilience required to claim a leadership role in the global lithium supply chain.

Recent Comments